Induction Heating Furnace for Hot Rolling

Features:

1.Application:Heat Treatment for Steel bar,Billet,Steel strip,Deformed bar,Carbon steel,Special Steel

2.Available Power:100KW-10000KW

3.Non-standard Product:Professional Customization

Product Detail

Application Video

Product Tags

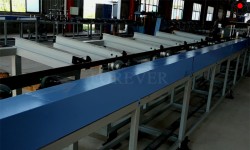

Forever Furnace Induction Heating furnace for hot rolling is non-standard product.The user need to tell us the material grade,outline dimension, heating temperature and production capacity.Our engineer will design induction coil according to user’s specific requirements. Sometimes we will equip with feeding and discharging device with heating furnace for hot rolling.PlC control or relay control will depend on the specific production status.

Advantages of induction heating system for hot rolling

1.Hot rolling process can reduce energy consumption and reduce the cost greatly.The metal shaping is high but deformation resistance is low, which reduce the energy consumption of metal deformation.

2.Hot rolling can improve processing performance of metals and alloys.

3.Hot rolling will be usually used for large casting and will rolled in large quantity, which not only improves productivity but also improve the rolling speed and creates conditions for continuous rolling and automatic rolling.

Application for Forever Furnace Heating Furnace for Hot Rolling

1.For general engineering and structural steel sheet, strip, for pipe, cold-rolled materials, bicycle parts.

2. For cold rolling, deep drawing products.

3.Stamping parts for cars,tractors,lifting machinery and small light industrial machinery.

4.Pipeline for oil and gas transportation.

5. Automobile frames, beams

6.Auto steel strip.

Forever Furnace can not only supply excellent quality heating furnace for hot rolling but also we can give the most suitable solutions for forging heating equipment. Welcome to contact us.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.