Quenching and tempering furnace

Features:

● Application: Heat treatment line for long bar, long shaft, long round bar

● Size : ø 10-150mm

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

Quenching and tempering furnace

● Application: Quenching and tempering for round bar, round rod, hydraulic rod

● Material: SC45, 40Cr, 42CrMo

● Diameter: 60-150mm (solid bar)

● Length: 2000-6000mm

● Quenching heating temperature: 950±10 ℃

● Tempering heating temperature: 650±10 ℃

● Input voltage: 380±10%

● Productivity: 2000kg/hr

Material performance requirements

● Surface hardness HRC22-27, Min.hardness HRC22

● Uniform hardness: the hardness tolerance is within 2-4 degree

● The organization must be uniform and the mechanical properties meet the standards

Yield strength> 50kgf / mm2

Tensile strength> 70kgf / mm2

Elongation> 17%

Induction heater design

| Item | Specification | Range | Length(m) | Induction heater |

| 1 | 60 | 45-60 | 2-6 | GTR 60 |

| 2 | 85 | 65-85 | 2-6 | GTR 85 |

| 3 | 115 | 90-115 | 2-6 | GTR 115 |

| 4 | 150 | 120-150 | 2-6 | GTR 150 |

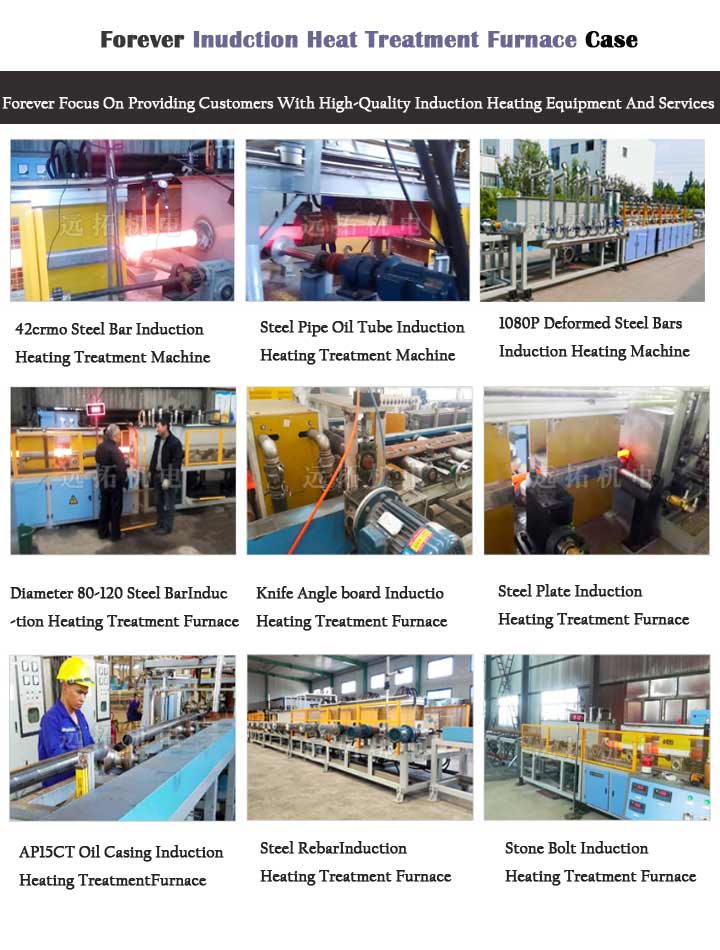

Forever quenching and tempering furnace advantages

● Accurate temperature control–Adjust heating temperature to the setting value

● No deformation for part, no need straightening machine

● Automatic rejection system–Ensuring the part quality after quenching & tempering

● Measurement meter for water flow, pressure and temperature.

● Suitable for 24 hours continuous working mode

● No spark during part running process

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !