Round bar induction heat treatment equipment |FOREVER

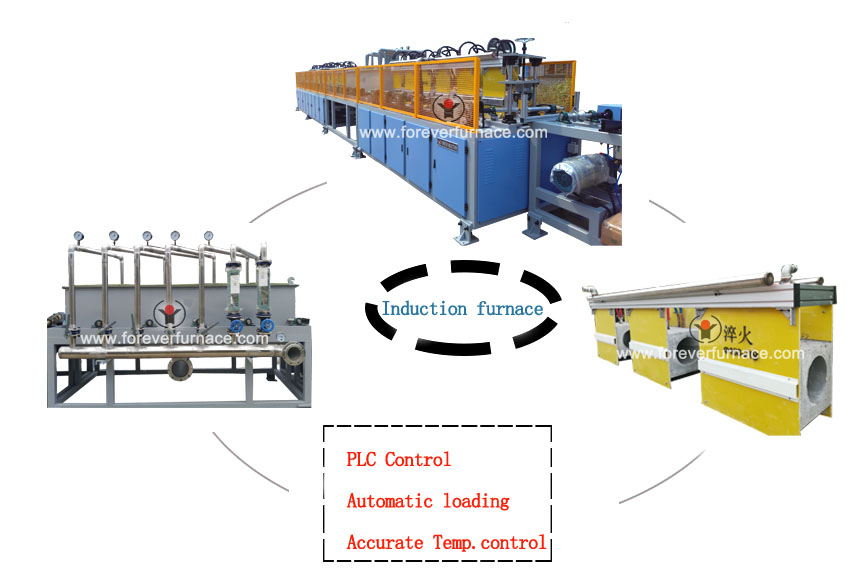

Features:

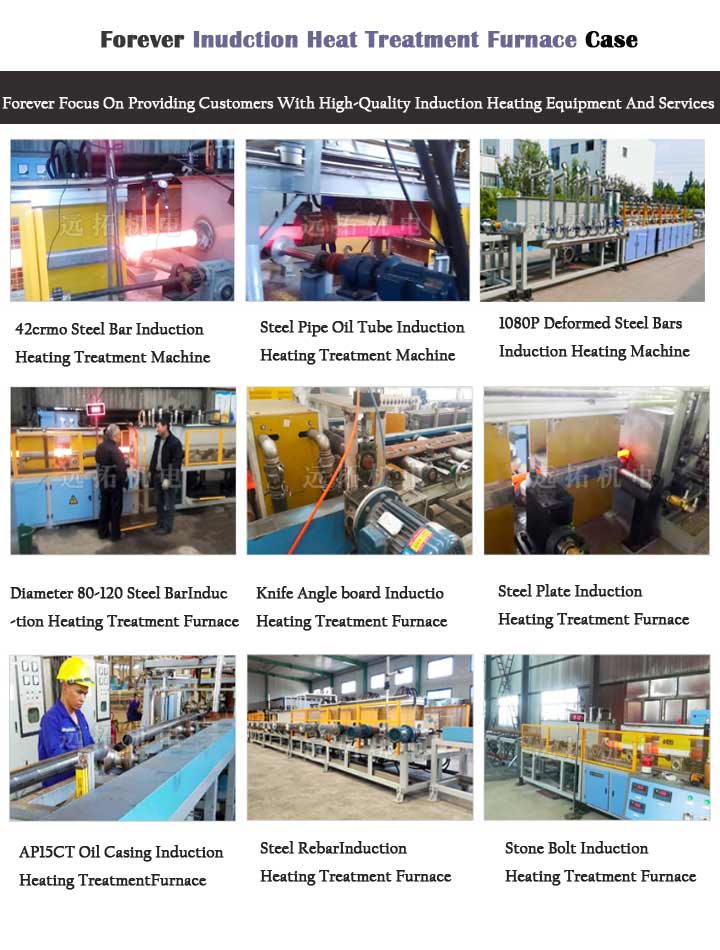

● Application: Heat treatment line for long bar, long shaft, long round bar

● Size : ø20mm or more

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

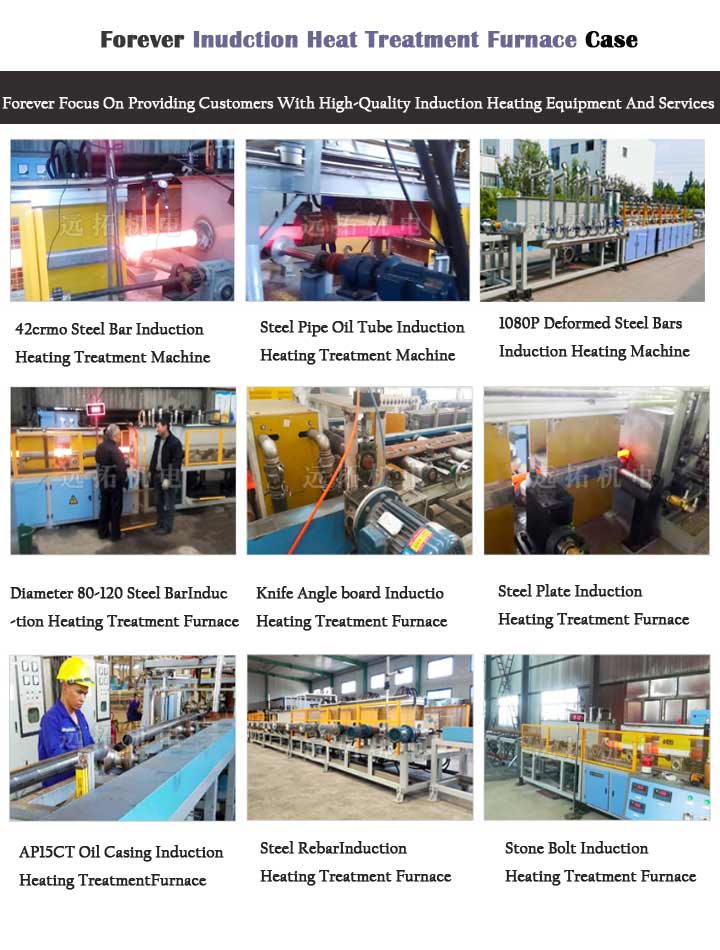

Forever is devoted to the production and design of round bar heat treatment equipment for more than 13 years. The technology is mature and stable, and the operation is reliable. The round bar heat treatment equipment has a key operation, that means one person can control the production of the whole heat treatment line. There is complete data monitoring, process record, customized man-machine interface to display the production parameters.

● Equipment name: Round bar heat treatment equipment

● Equipment brand: Forever

● Non standard Customization: Yes.

● Workpiece material: Carbon steel, alloy steel, etc.

● Delivery time: Within 30 days

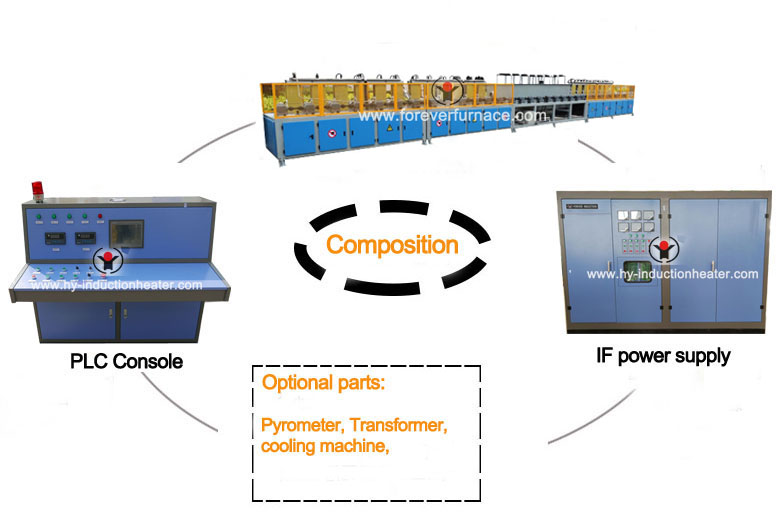

The configuration of round bar heat treatment equipment

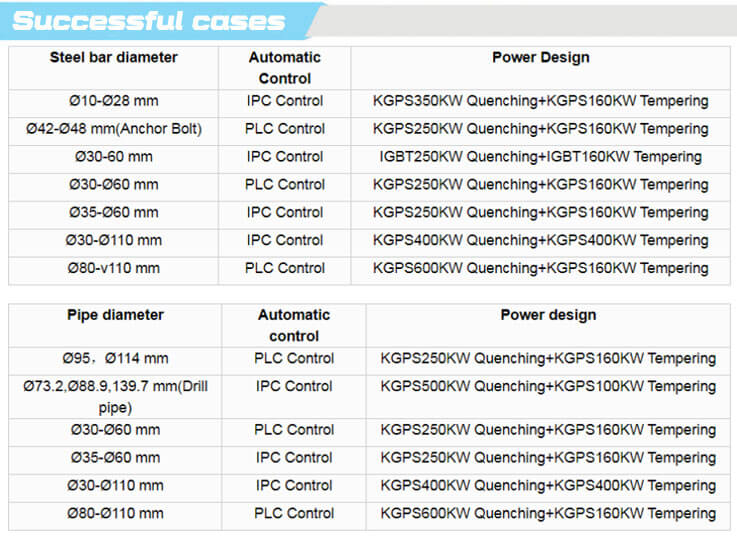

● Medium frequency quenching power supply range: KGPS160-1300KW

● Intermediate frequency tempering power supply range: KGPS160-750KW

● Quenched and tempered inductors (including capacitor bank, waterway, circuit, etc.)

● Closed cooling system for medium frequency power supply and inductor

● Copper bar connection (Connection cable between power cabinet and induction furnace)

● Input and output system (rollers are made of 304 non-magnetic stainless steel, the workpiece rotates and feeds at the same time at the same speed, and runs smoothly, the speed is adjustable, the heating is more uniform, corrosion resistance, long service life)

● Quenching and tempering sprinkling system

● The function of the remote console (including frequency control and temperature control, Huayan industrial computer, remote start-up, etc.). Only one person can operate the whole set of induction hardening and tempering equipment saving labor and cost.

● Quenching and tempering infrared temperature measuring device (equipped with Raytek infrared thermometer to display the temperature of the workpiece in real time, so that the user can see the temperature uniformity of the workpiece at any time during the quenching and tempering process)

● PLC control system (control of the whole mechanical part of the operation, man-machine interface, full digital, highly humanized operation)

Forever has many years of practical experience in the design, process, manufacturing and management of the round bar heat treatment furnace. The intermediate frequency power supply adopts SCR intelligent series resonant design, which has features of high power factor, small harmonic component and fast heating speed.

After treatment, the round has no crack bending and can meet standard in toughness, tensile strength, yield strength and hardness.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Welcome your inquiry for quenching and tempering induction heat treatment equipment !