Steel Ball Rolling Froming Induction Heating Equipment

Features:

1.Available Power:100KW-8000KW

2.Available Frequency:500Hz-8000Hz

3.Heating Diameter:Ø16-150MM

4.Exact Temperature Control and Automatic Operation

Product Detail

Application Video

Product Tags

Forever Furnace Steel ball forming induction heating equipment is used for steel ball manufacturing plant.We can design and manufacture steel ball rolling equipment according to your specific requirement.

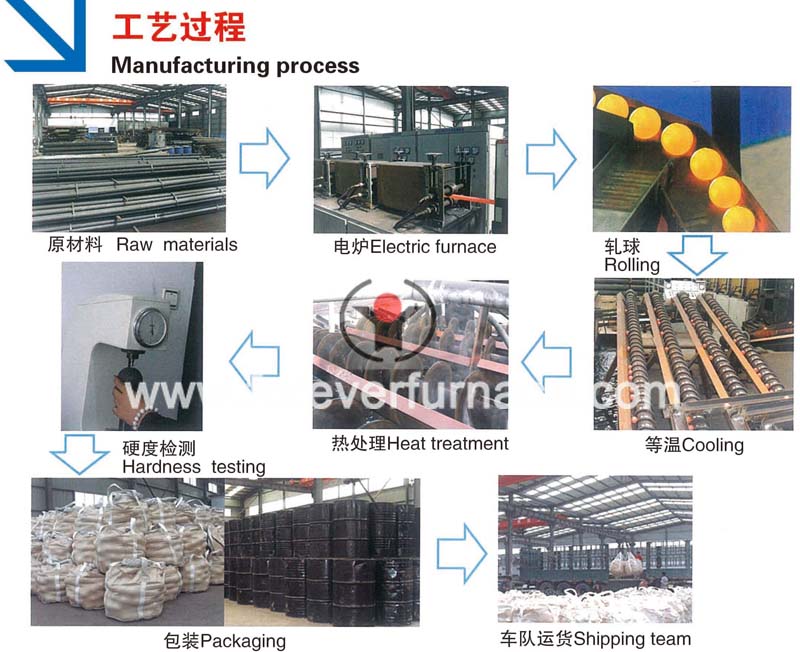

The Process for steel ball rolling production line

1.After steel bar inspection,shearing to semi-finished steel bar by specified length.

2.Before rolling the semi-finished steel bar,it need to be heated to proper temperature in the continuous heating furnace.

3.After red state of billet is fed into the ball rolling mill,it will rotate between the two rollers with special spiral groove,and then continuously rolling as steel ball.Each ball rolling mill can roll 60-120 steel ball per minute.

4.Red state steel ball after rolling will immediately put into on-line heat treating machine for quenching-tempering treatment,make steel has high and even hardness.

5.After inspection,the qualified products will send to finished goods warehouse,then deliver to customer after packaging.

The Common Current Frequency for Steel Ball Rolling Equipment

1.High frequency heating:100~500KHZ,usually use 200~300KHZ,mainly used for medium and small work piece.

2.Medium frequency heating:500~10000HZ,usually use 2500~8000HZ,mainly used for shaft with bigger diameter and large gear.

3.Line frequency:50HZ,mainly used for surface quenching with bigger part diameter.

Forever Furnace can not only supply good quality steel ball rolling equipment,but also we are specialist of steel ball hot rolling equipment who can give you the most suitable and energy saving solutions.

Overseas manager: Tom Wang

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.